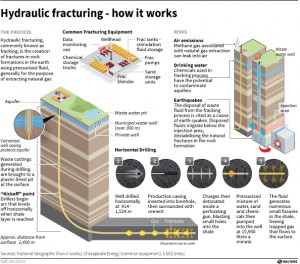

Hydro-fracking or Natural Gas Hydraulic Fracturing is the fracturing of rock by pressurized liquid to extract natural gas. The process was created by Haillburton Inc., Schlumberger Inc., and Messina Inc. in 1947. The technique is mixing sand, water, and chemicals in which the mixture is injected at high pressure into a wellbore to generate small fractures (< 1mm) along with gas such as petroleum, uranium-bearing solution, and brine water may travel to the well. Wellbore is a drill hole used for the purpose of withdrawal or examination of natural resources such as natural gases or oil where a well may be produced as resource for extended period. The most common natural gas in Shale gas which are fine-grained sedimentary rocks that can be rich sources of petroleum. Natural gas is used for 24% of America’s energy demand. It heats 51% of American households.

Hydro-fracking or Natural Gas Hydraulic Fracturing is the fracturing of rock by pressurized liquid to extract natural gas. The process was created by Haillburton Inc., Schlumberger Inc., and Messina Inc. in 1947. The technique is mixing sand, water, and chemicals in which the mixture is injected at high pressure into a wellbore to generate small fractures (< 1mm) along with gas such as petroleum, uranium-bearing solution, and brine water may travel to the well. Wellbore is a drill hole used for the purpose of withdrawal or examination of natural resources such as natural gases or oil where a well may be produced as resource for extended period. The most common natural gas in Shale gas which are fine-grained sedimentary rocks that can be rich sources of petroleum. Natural gas is used for 24% of America’s energy demand. It heats 51% of American households.

As of 2012 there are 2.5 million jobs available in hydro-fracking and more than one million of those jobs are in the US. Although fracking provides millions of jobs these jobs are dangerous, exposing workers to chemicals with long term effects that are still unknown to us. Many people wonder if hydro-fracking will bring the U.S. more energy independence but in fact it won’t. Much of the gas being fracked will end up in Europe because gas will flow to the highest bidder. Once the gas flows overseas the prices will rise in the U.S. and the gas prices will be dictated by the world market.

Challengers of hydraulic fracturing point to some environmental risks including reduction of fresh water, contamination of ground water, corruption of the air, noise pollution, migration of gases and hydro-fracking chemicals to the surface contamination from spills and flow-back, and also health effects. Each time they build a well they need 3,500,000 gallons of water when fracking one well. It is stated that upwards of 70% of fracking fluid remains in the ground after fracking and is not biodegradable. Researchers suspect 65 of the components used in hydro-fracking are hazardous to humans.

Natural gas is cleaner than oil and a lot cleaner than coal but it’s still a fossil-fuel that enhances greenhouse gases like methane and carbon dioxide (CO2) into the atmosphere. Although the leakage of methane outweighs the climate benefit of natural gas versus coal. Natural gas gives off 50% of the carbon dioxide emissions as coal. Methane’s warming potential far exceeds that of coal; methane traps heat up to 105 times more effectively than the mass of carbon dioxide.

Scientists have identified cancer-causing chemicals like “BTEX” benzene, toluene, ethylbenzene, and xylene and 596 other chemicals are being used in hydro-fracking, but nobody knows for sure what chemicals are pumped underground. In 2005, the Bush administration supported an energy bill that excuses hydro-fracking from the Safe Drinking Water Act. The Safe Drinking Water Act is a federal law that ensures the quality of American drinking water. The law protects drinking water and its sources: rivers, lakes, streams, and ground water wells although they do not regulate private wells which serve fewer than 25 persons. The peculiar thing is that companies that participate in hydro-fracking keep their chemical mixtures a secret to the people that allow them to engage in hydraulic fracturing on their land. This is peculiar because if they were using environmental friendly chemicals during the process of fracturing they wouldn’t have to hide the truth.

The hydro-fracking chemicals used within the mixture to help obtain natural gases becomes sealed deep underground, there’s a good chance the chemicals enter private wells destroying drinking water quality. When the natural gas comes to the surface, it carries millions of gallons of contaminated water with fracking fluid and radium that is stored in on-site ponds that can leak or overflow into streams connecting to major bodies of water. And in many other cases the poisoned water is transported to water treatment plants that cannot handle radioactive water. That contaminated water is then sent downstream to the town’s drinking water. The above serious long term threats to water quality are one of the many oppositions people have to hydro-fracking, especially in the Marcellus Shale Region where important watershed provides drinking water to 16 million people.

There are a few companies in the world that are planning an alternative to hydro-fracking by using sunlight and nanoparticles to produce natural gas from wastewater. They hope that it will alleviate the need to drill for gas using hydraulic fracturing. I believe that if we can find a safer non-toxic way to obtain natural gasses then I am all for it but not until then. I firmly believe hydraulic fracturing is not in the best way to obtain natural gases and if we continue global warming will worsen and more drinking water will be contaminated.

Videos:

Fracking Hell: The Untold Story

Hydraulic Fracturing 3D Animation

Resources: