The news today is often dominated by stories of climate change and the growing need of society to divest itself of fossil fuel use. As transportation makes up almost a third of global energy expenditures, the growth of pure electric and hybrid vehicles are offering an exciting alternative to business as usual in the automotive industry.

One of the more attractive features of electric vehicles is their improvement over the inefficiencies of conventional combustion engine based vehicles. The typical internal combustion engine (ICE) can lose up to 62% of the fuels energy just in the engine. The Tesla Model S, however, has been purported to achieve between 85% to 95% energy transfer to the wheels. A vast improvement by any measure.In part this is achieved through simplicity of purely electric system; instead of the hundreds of components found in a typical ICE based vehicle, Teslas’ typically have only have four major components:

Energy Storage System (battery)

Power Electronics Module (main computer )

Electric Motor

Sequential Manual Transmission

In the Tesla Model S, electrical power drawn from the lithium ion batteries is converted into rotational force (torque) by the electric motors which then apply this torque to the transmission to rotate the wheels of the vehicle. This is beneficial in that the Model S, by using electricity as a primary energy source, could theoretically be driven without contributing any green house gases to the environment. However, the lack of ubiquitous quick charging stations means that driving in excess of it’s ~200 mile battery range means that long distance travel isn’t really practical with this system yet.

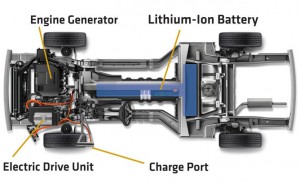

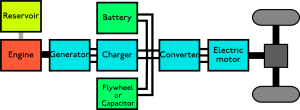

The Fisker Karma, however, is unique in that it uses a ‘series-hybrid’ system. In a series-hybrid system, an ICE only turns an electric generator instead of applying torque directly to the drive train, as a conventional vehicle does.

The generator provides power for driving electric traction motors, which are the only form of propulsion. The internal combustion engine is mechanically disconnected from the driving wheels. The generator, traction motors usually have an electric buffer battery between. This arrangement allows for a smaller generator engine to be used compared to the size of a conventional direct drive engine. The traction motors can receive electricity from the battery or generator or both. The traction motors, depending of the size of the battery bank, will in many cases have most of the energy provided only by the electric battery, which may be charged from external an sources such as the electricity grid. However, the on board generator can recharge the battery and power the traction motors directly on long journeys.

Both the Fisker and the Tesla are pivotal improvements over typical combustion engine powered vehicles in that they don’t rely on gasoline as the primary means to power their drive trains. While the Tesla utilizes the primary power stored, electricity, the Fisker hybrids when using their hybrid mode, convert gasoline to electricity that is then used to power the electric motors.

While the Fisker design proves more adaptable to the various energy sources available in the United States, and is in the same approximate price region as Tesla’s fleet ($90,000-100,000), it would seem that for now, the Fisker is perhaps the best choice for those wanting to lessen their negative environmental impact while still retaining the versatility and freedom of travel that conventional vehicles offer.

These vehicles, for the benefit they provide, will undoubtedly grow in market share; as the offerings from pure ICE based vehicles are proving more poisonous and problematic with every increase of the thermometer.

http://en.wikipedia.org/wiki/Hybrid_vehicle_drivetrain#Series_hybrid

http://en.wikipedia.org/wiki/Fisker_Karma

http://auto.howstuffworks.com/tesla-roadster.htm

http://exoticcars.about.com/od/guidedtours/ss/Fisker-Karma_2.htm

http://www.consumerenergycenter.org/transportation/consumer_tips/vehicle_energy_losses.html